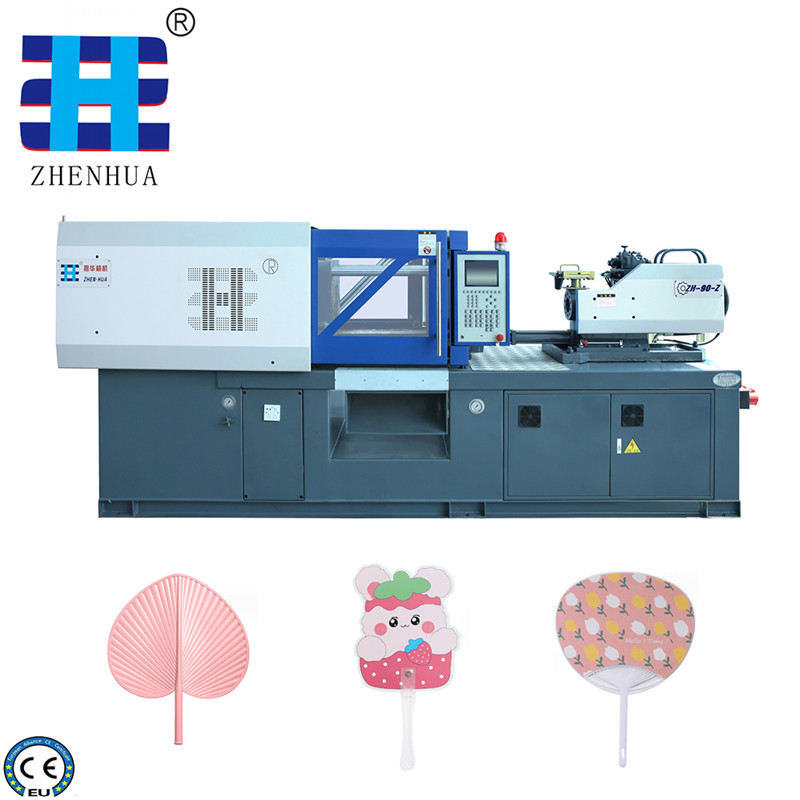

88ton Injection Molding Machine for Fuzz Removing Machine

|

Technical Parameter |

Unit |

ZH-88T |

|||

|

A |

B |

C |

|||

|

Injection Unit |

Screw Diameter |

mm |

28 |

31 |

35 |

|

Theoretical Injection Volume |

OZ |

3.4 |

4.1 |

5.2 |

|

|

Injection Capacity |

g |

73 |

90 |

115 |

|

|

Injection Pressure |

MPa |

245 |

204 |

155 |

|

|

Screw Rotation Speed |

rpm |

0-180 |

|||

|

Clamping Unit

|

Clamping Force |

KN |

880 |

||

|

Toggle Stroke |

mm |

300 |

|||

|

Tie Rod Spacing |

mm |

360*360 |

|||

|

Max.Mold Thickness |

mm |

380 |

|||

|

Min.Mold Thickness |

mm |

125 |

|||

|

Ejection Stroke |

mm |

65 |

|||

|

Ejector Force |

KN |

22 |

|||

|

Thimble Root Number |

pcs |

5 |

|||

|

Others

|

Max. Pump Pressure |

Mpa |

16 |

||

|

Pump Motor Power |

KW |

11 |

|||

|

Electrothermal Power |

KW |

6.5 |

|||

|

Machine Dimensions (L*W*H) |

M |

3.7*1.0*1.5 |

|||

|

Machine Weight |

T |

3.2 |

|||

Injection molding machines can be used to produce various spare parts for hair ball trimmers. The specific spare parts used depend on the design and functional requirements of the hair ball trimmer. Generally speaking, the spare parts of hair ball trimmer may include the following types: Shell: The shell of the hair ball trimmer is usually made of plastic injection molding. The injection molding machine can manufacture the plastic parts of the shell, such as the body shell, buttons, switches, etc.

Cutter Head: A hair ball trimmer uses a cutter head to trim hair balls on clothing. The cutter head is usually composed of a sharp cutting blade. Injection molding machines can manufacture plastic parts for the cutter head holder and blades.

Circuit board: The hair ball trimmer usually has the function of electric drive. The injection molding machine can manufacture the plastic bracket and fixing part of the hair ball trimmer's circuit board.

Battery compartment cover: Hair ball trimmers usually use batteries as power sources, and an injection molding machine can make the plastic parts of the battery compartment cover. Accessories: Depending on the design and functional requirements of the hair ball trimmer, other spare parts may be required, such as pulleys, motor brackets, buttons, etc. These spare parts can also be manufactured using an injection molding machine.